Let’s face it, packaging is the first thing people notice about your product. Printing techniques play a huge role in making that first impression unforgettable. These methods don’t just make your packaging look good; they also add texture, durability, and an overall premium feel. In this guide, we’ll dive into some of the most popular printing techniques and see how they can take your packaging to the next level.

- What Are Packaging Printing Techniques?

- Popular Packaging Printing Techniques

- 1. Offset Lithography: Precision for Detailed Designs

- 2. Flexography: Versatility and Speed

- 3. Digital Printing: The Customization Powerhouse

- 4. Gravure Printing: Consistency at Scale

- 5. Screen Printing: Bold and Durable

- 6. Hot Foil Stamping: The Luxury Touch

- 7. Embossing and Debossing: Adding Dimension

- 8. Spot UV Printing: Highlighting Key Details

- 9. Lamination: Stylish and Protective

- How to Choose the Right Technique

What Are Packaging Printing Techniques?

Packaging printing techniques are specialized methods used to apply designs, text, and branding to product packaging. They not only enhance the aesthetic but also improve functionality, appeal, and marketability.

Popular Packaging Printing Techniques

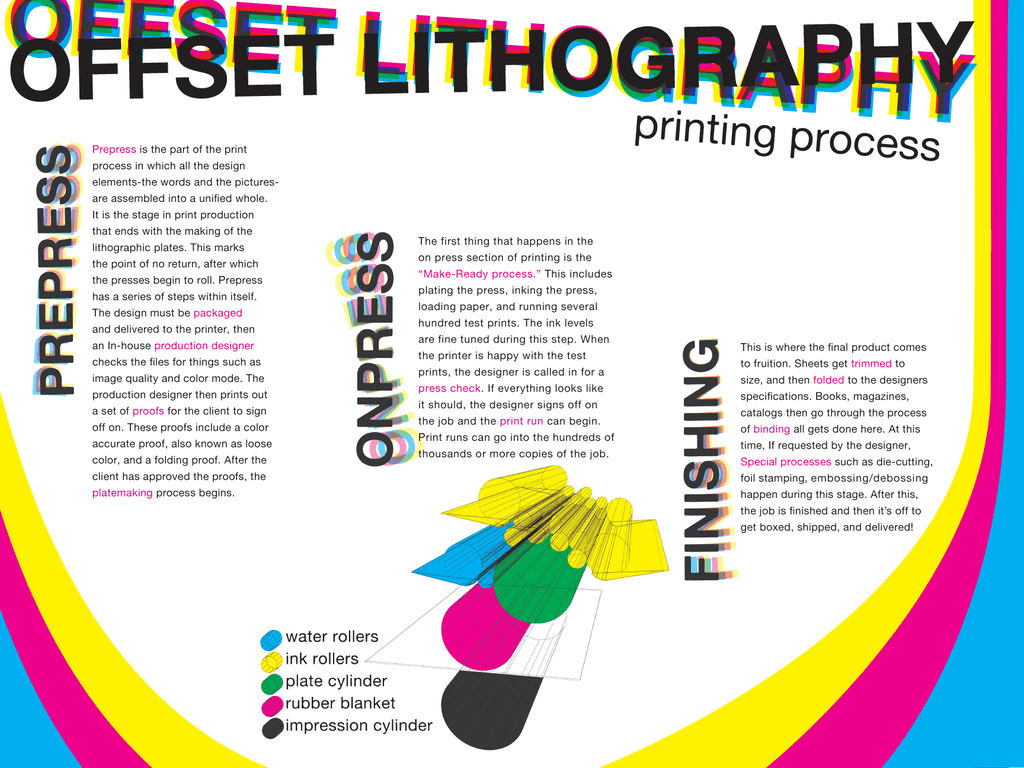

1. Offset Lithography: Precision for Detailed Designs

What’s the Deal?

Offset lithography is all about precision. It transfers an image from a plate to a rubber blanket and then to the printing surface. This technique is a favorite for its consistency and sharp results.

Why It’s Awesome

- Sharp Looks: Produces vibrant, detailed images perfect for intricate designs.

- Smooth Finish: Gives your packaging that polished, professional feel.

- Great for Bulk: If you’re making thousands of units, this technique is cost-effective and reliable.

Best For

Luxury packaging, detailed illustrations, and large-scale product lines.

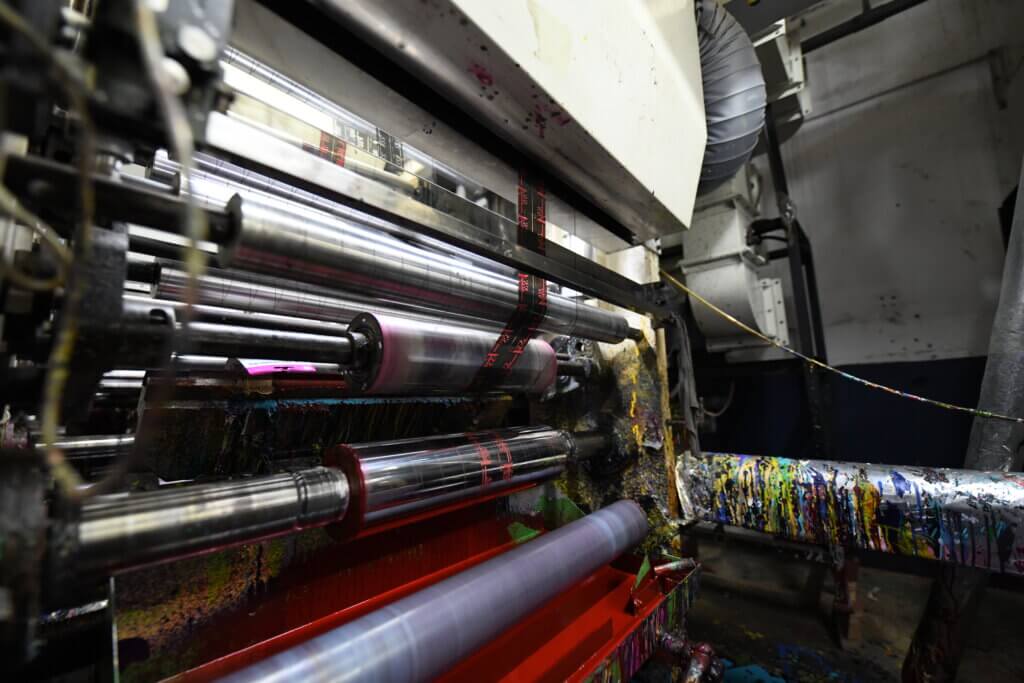

2. Flexography: Versatility and Speed

What’s the Deal?

Flexography uses flexible relief plates to print on just about anything—plastic, paper, metallic films—you name it.

Why It’s Awesome

- Adaptable: Great for uneven or textured surfaces.

- Quick Turnaround: Perfect for high-volume runs with fast-drying inks.

- Bold Designs: Excels at creating repetitive patterns and bold graphics.

Best For

Food packaging, retail bags, and corrugated boxes.

3. Digital Printing: The Customization Powerhouse

What’s the Deal?

Digital printing skips the plates and goes straight from a digital file to the printer. It’s like the Swiss Army knife of printing—flexible and super customizable.

Why It’s Awesome

- Quick and Easy: Perfect for short runs and prototypes.

- Personal Touch: Ideal for adding QR codes, names, or unique designs.

- Eco-Friendly: Reduces waste since there’s no setup or plates required.

Best For

Personalized packaging, prototypes, and limited-edition products.

4. Gravure Printing: Consistency at Scale

What’s the Deal?

Gravure printing ( also known as rotogravure printing) is your go-to for high-volume production. It uses a cylinder etched with your design to create clean and consistent prints.

Why It’s Awesome

- Super Sharp: Perfect for detailed imagery and vibrant colors.

- Reliable: Delivers consistent results over long runs.

- Flexible Materials: Works like a charm on foils and plastics.

Best For

Flexible packaging, premium magazines, and detailed labels.

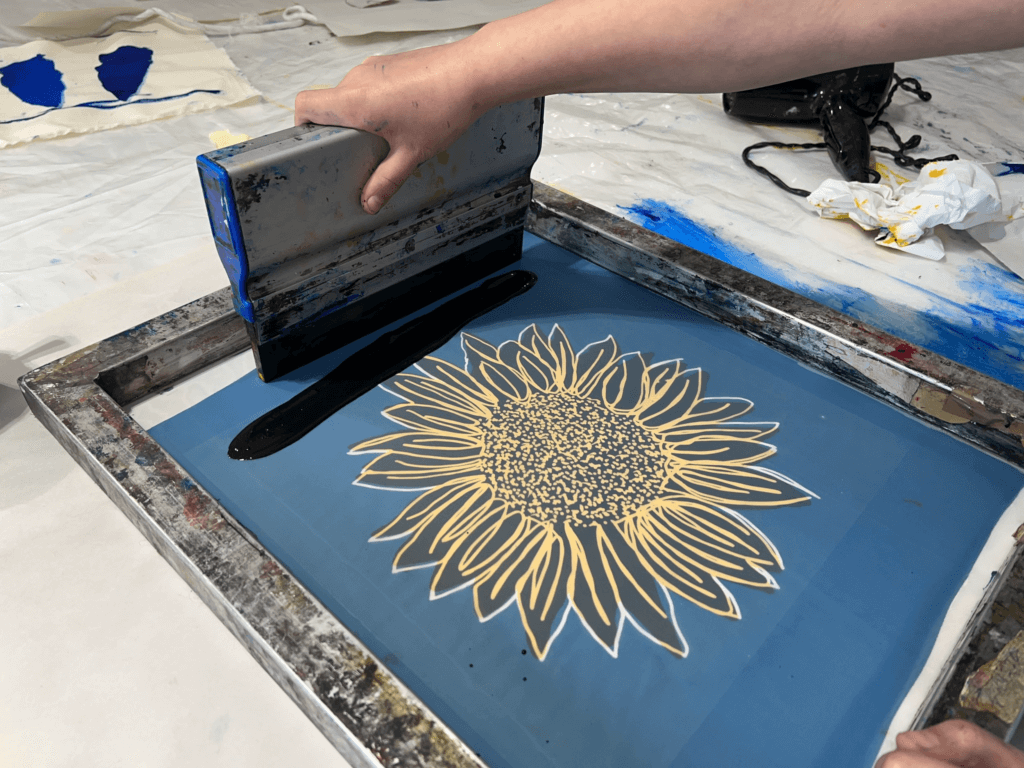

5. Screen Printing: Bold and Durable

What’s the Deal?

Screen printing (also called Silk Screen Printing) layers ink through a stencil onto your packaging surface. It’s known for its bold, durable designs.

Why It’s Awesome

- Vivid Colors: Creates bold, opaque finishes that pop.

- Works Anywhere: Great for glass, plastic, fabric, and more.

- Built to Last: Perfect for products that need to stand up to wear and tear.

Best For

Bottles, jars, and promotional packaging.

6. Hot Foil Stamping: The Luxury Touch

What’s the Deal?

Hot foil stamping uses heat and pressure to add shiny metallic or pigmented accents. It’s all about that wow factor.

Why It’s Awesome

- Luxury Look: Adds a shiny, high-end finish.

- Feels Premium: Smooth metallic textures elevate the tactile experience.

- Eco Options: Now available with sustainable foil materials.

Best For

Gift boxes, luxury goods, wine bottles, and jewelry packaging.

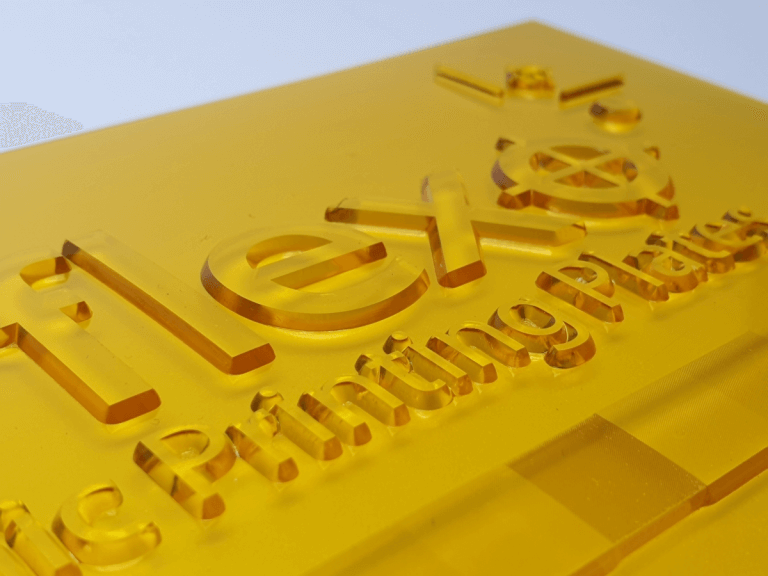

7. Embossing and Debossing: Adding Dimension

What’s the Deal?

Embossing raises a design, while debossing creates a recessed effect. Both add a premium feel to your packaging.

Why It’s Awesome

- Stands Out: Highlights logos and patterns in a big way.

- Feels Special: Adds texture that engages your customer’s sense of touch.

- Premium Vibes: Takes your brand image to the next level.

Best For

High-end branding, logos, and decorative patterns.

Learn more about Embossing or Debossing, Which is Better for Your Packaging?

8. Spot UV Printing: Highlighting Key Details

What’s the Deal?

Spot UV is all about contrast. It adds a glossy coating to specific areas, making them pop against a matte background.

Why It’s Awesome

- Eye-Catching: Creates a polished effect that draws attention.

- Protective: Shields critical areas like logos or text.

- Focus Points: Perfect for emphasizing key elements of your design.

Best For

Business cards, luxury boxes, and product labels.

9. Lamination: Stylish and Protective

What’s the Deal?

Lamination coats your packaging with a thin film for extra durability and style.

Why It’s Awesome

- Multiple Finishes: Choose matte, glossy, or soft-touch.

- Protects: Keeps your design safe from moisture and wear.

- Tactile Appeal: Soft-touch laminations feel especially premium.

Best For

Retail packaging, book covers, and premium product boxes.

Learn more about lamination: Matte vs. Glossy Finishing: Which One is Better For Your Brand?

How to Choose the Right Technique

Choosing the best printing method depends on your product, budget, and brand image. Consider:

- Material Compatibility: What works for your material type (e.g., paper, plastic)?

- Production Volume: Short or large-scale?

- Brand Identity: Are you aiming for luxury, sustainability, or bold visuals?

Quick Recap:

- Offset Lithography: Precise, great for large-scale runs.

- Digital Printing: Best for personalization and short runs.

- Screen Printing: Vibrant and durable for specialty items.

- Hot Foil Stamping: Adds luxury appeal.

Conclusion: Make Your Packaging Unforgettable

Printing techniques can elevate your packaging from ordinary to extraordinary. Whether you’re chasing sustainability with water-based inks or adding a luxe touch with hot foil stamping, the right choice reflects your brand’s values and resonates with your audience. Start today by identifying what matters most to your brand and make your packaging unforgettable!