- Delivering on the Plastic-Free Promise

- Introduction: Designing Sustainability Beyond the Product

- The Challenge: Scaling Sustainability Without Compromise

- The Solution: Full-Cycle Packaging Innovation from INNORHINO

- Outcome: A Packaging Ecosystem That Scales With the Brand

- Looking Ahead: Future-Proofing Sustainable Packaging

- Frequently Asked Questions

Delivering on the Plastic-Free Promise

For brands committed to sustainability, developing a plastic-free product is only part of the equation. The packaging must reflect that same commitment—delivering on shelf life, shipping durability, and consumer appeal, all without compromising environmental values.

Introduction: Designing Sustainability Beyond the Product

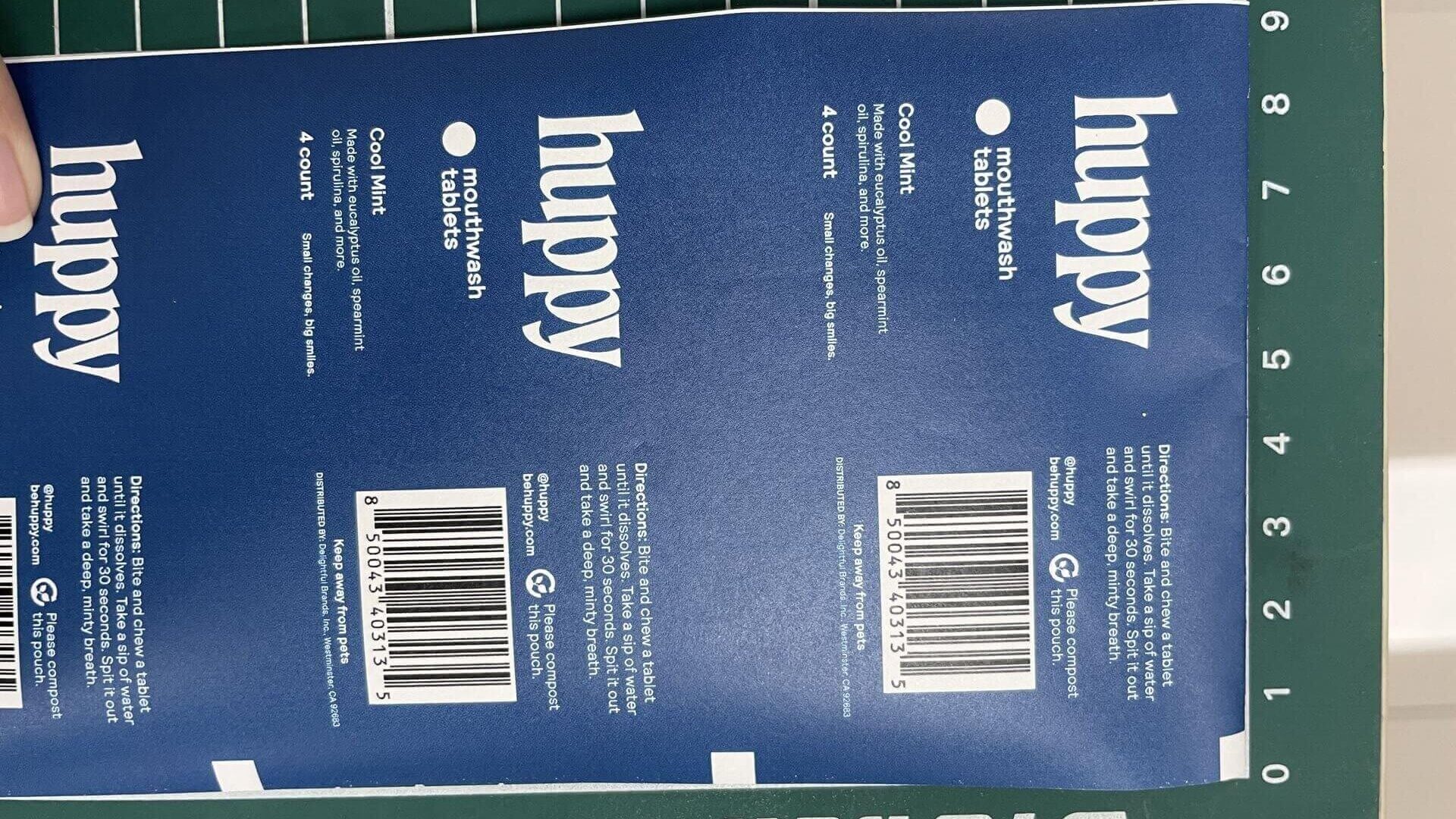

Huppy (Huppy Toothpaste Tablets), a leading oral care brand in North America, has built its identity around a bold mission: offering 100% plastic-free, non-GMO toothpaste tablets in travel-ready formats. However, its existing packaging supply chain fell short of the growing demands—struggling with flexible MOQs, consistent lead times, aesthetic precision, and the complete elimination of plastic. The brand also faced complex technical requirements, from finding plastic-free foil alternatives to achieving high-consistency aluminum packaging that met both performance and branding standards.

That’s where INNORHINO came in. Through end-to-end materials innovation, precision engineering, and tightly coordinated supply execution, the partnership redefined what’s possible in plastic-free oral care packaging.

The Challenge: Scaling Sustainability Without Compromise

Huppy’s mission is clear: eliminate plastic waste from oral care. But mission-driven packaging often encounters hurdles:

- Inflexible MOQs (Minimum Order Quantities)

- Long lead times and unreliable fulfillment

- Difficulty balancing visual branding with sustainable materials

- Need for advanced barriers without resorting to plastic

The brand needed a packaging partner that could match its bold ethos with equally bold engineering. Moisture-sensitive tablets, visual branding standards, and scale-readiness made the stakes high—and the room for error low.

The Solution: Full-Cycle Packaging Innovation from INNORHINO

1. Compostable Multilayer Pouches: Function Meets Philosophy

To store toothpaste tablets safely without plastic, INNORHINO developed a proprietary triple-layer pouch structure made from PLA and a Japanese-patented biodegradable foil.

Key Innovations:

- Solved for oxygen and moisture barriers using plastic-free layers.

- Resolved technical failures like bubbling, delamination, and sealing breakdowns via rapid prototyping.

- Maintained a compostable profile with visual clarity and printable surface integrity.

These pouches preserved tablet integrity and elevated the unboxing experience without compromising the compostability goal.

2. Custom-Engineered Aluminum Tins: Aesthetic Precision Meets Practicality

For a more premium and travel-friendly experience, INNORHINO reimagined aluminum tins with a seamless double-lid design—screw-free, flush, and elegantly branded.

Engineering Highlights:

- Transitioned to post-forming painting to preserve color integrity post-deep drawing.

- Integrated SPA UV finishes to add optical brilliance and tactile quality.

- Delivered embossed branding and consistent forms across SKUs.

The result? A luxury feel that remained true to the zero-plastic mission.

3. Process Control and Transparent Execution

INNORHINO didn’t just deliver materials—they managed the manufacturing ecosystem:

- Developed custom tooling with defined testing benchmarks.

- Rejected early pressure to ship unfinished goods, upholding high quality thresholds.

- Provided visual process maps and risk management documentation for total transparency.

This approach minimized disruptions and aligned teams across continents.

Outcome: A Packaging Ecosystem That Scales With the Brand

Today, the new Huppy packaging lines are live and featured across their DTC platforms and retail channels. INNORHINO has become a cornerstone in Huppy’s sustainability-driven supply chain.

Notable Results:

- Travel-friendly tinplate containers designed and produced to meet transitional format needs.

- Improved seal reliability and color consistency for long-term SKU growth.

- A unified brand experience that reinforces Huppy’s values at every touchpoint.

Looking Ahead: Future-Proofing Sustainable Packaging

The Huppy × INNORHINO project is a blueprint for how thoughtful design and agile engineering can overcome sustainability hurdles. Looking forward, the collaboration continues to explore:

- Bio-plastic innovations with sensory and aesthetic differentiation

- Advanced seal testing in biodegradable film structures

- High-consistency aluminum shaping for taller, more complex formats

For brands aiming to embed sustainability into every layer of their business, the packaging journey is far from cosmetic—it’s a core expression of identity and impact.

Frequently Asked Questions

What materials replaced plastic in Huppy’s packaging?

INNORHINO used a PLA-based triple-layer structure with biodegradable foil for pouches and engineered aluminum tins with post-forming paint and UV finishes.

Why is post-forming painting important for aluminum packaging?

Traditional pre-painted aluminum loses color consistency after deep drawing. Post-forming painting ensures even tone and preserves brand aesthetics.

How does this redesign align with Huppy’s sustainability goals?

The entire solution eliminated plastic, maintained compostability, and supported premium branding—all without compromising function.

What were the key challenges in developing plastic-free pouches?

Common issues included sealing failures, delamination, and bubbling, all of which were solved through iterative prototyping and technical refinements.

Can other brands replicate this approach?

Yes—with the right packaging partner. INNORHINO specializes in helping brands navigate technical and environmental trade-offs to deliver scalable, sustainable packaging solutions.