- Introduction: The Secret Strength Inside Every Box

- 1. Understanding How Flutes Work: Shock Absorbers vs. Sturdy Foundations

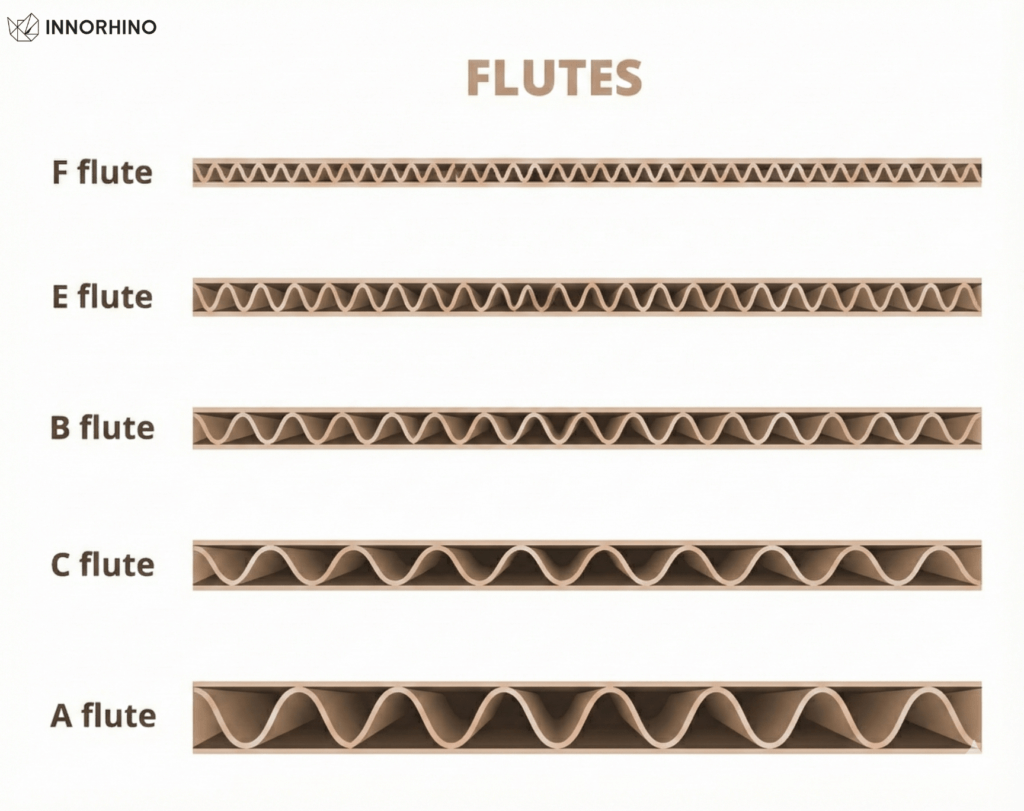

- 2. Meet the Flutes: Profiles of the Packaging Protectors

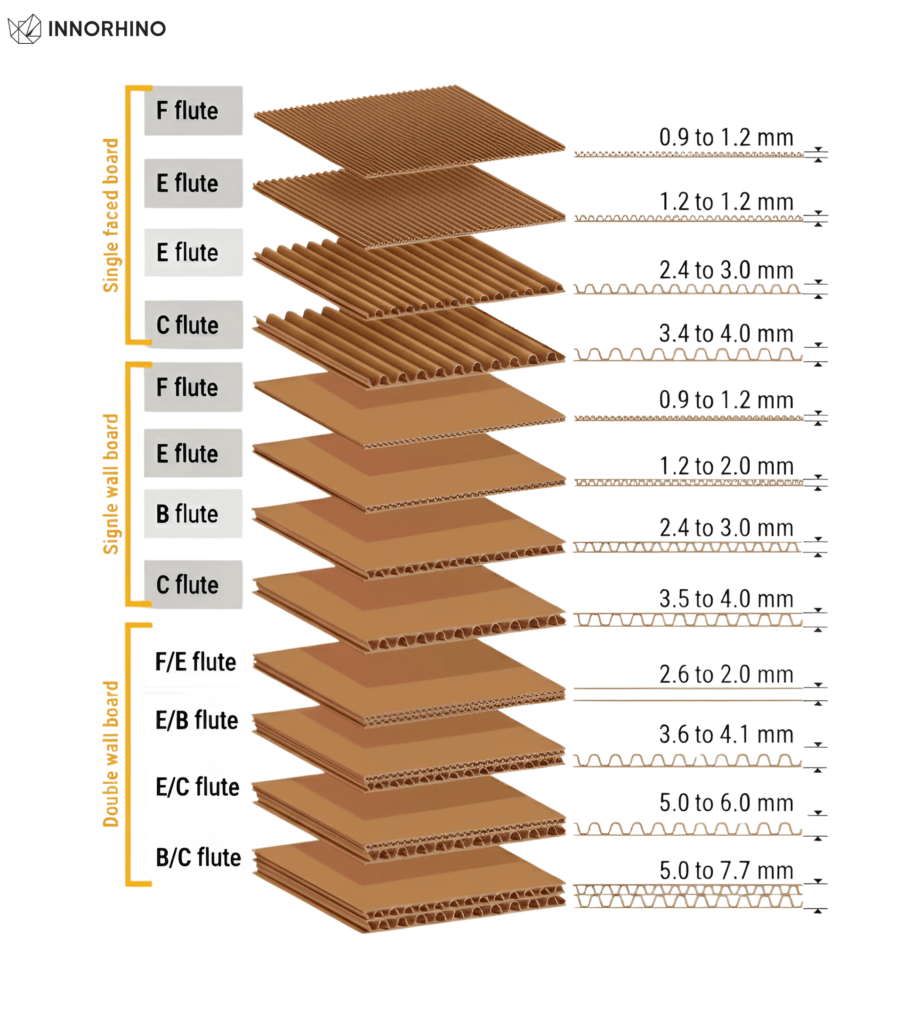

- 3. Corrugated Board Types: How Many Layers Do You Need?

- 4. Flutes at a Glance: Quick Comparison Table

- 5. How to Choose the Right Flute: Practical Scenarios

- 6. Eco-Friendly Packaging: Recycling Corrugated Cardboard

- Conclusion: Strong Packaging Starts with Smart Choices

- Frequently Asked Questions (FAQ)

Introduction: The Secret Strength Inside Every Box

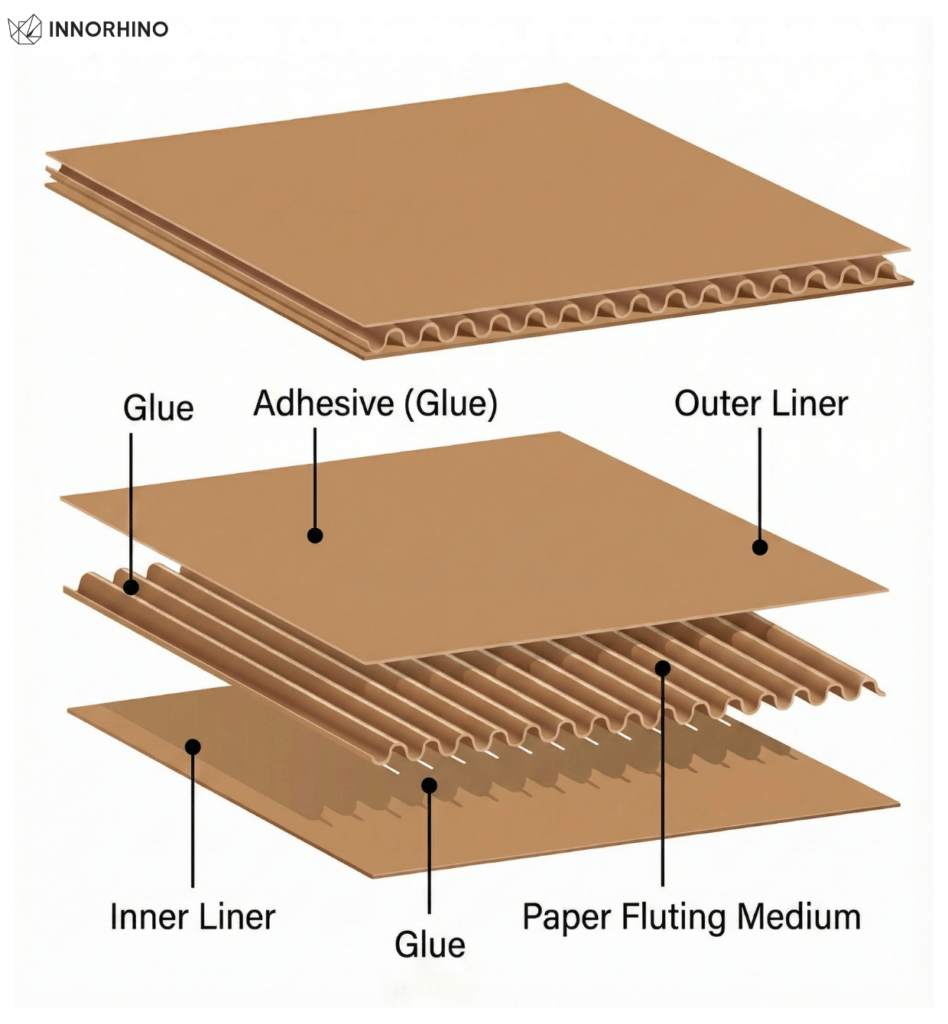

Think of a shipping box as a custom-fitted suit of armor for your product. While it may seem like nothing more than paper, the real strength comes from a hidden structural hero—the corrugated flute—the wavy, arched layer sandwiched between two flat sheets of linerboard.

This ingenious design, inspired by the natural strength of arch bridges, creates a lightweight yet incredibly strong material capable of protecting goods through bumps, drops, stacking pressure, and long-distance transit.

This beginner-friendly guide demystifies the most common corrugated flute types (A, B, C, E, F) and the board structures they build (single wall, double wall, triple wall). By the end, you’ll know exactly how to choose the perfect box for any product—fragile, heavy, luxurious, or industrial.

1. Understanding How Flutes Work: Shock Absorbers vs. Sturdy Foundations

To understand flute differences, picture two engineering concepts:

Tall, wide flutes (A-Flute) → Shock Absorbers

These behave like springy suspension systems. Their greater height creates more air space, giving them superior cushioning for fragile or impact-sensitive items.

Short, dense flutes (E-Flute, F-Flute) → Solid Foundations

These behave like tightly packed structural walls, offering excellent rigidity, crush resistance, and smooth surfaces for printing.

With that in mind, let’s meet the most widely used flute types.

2. Meet the Flutes: Profiles of the Packaging Protectors

2.1 A-Flute: The Master of Cushioning

Height: 4.5–5.0 mm Flutes per meter: ~108 Primary strength: Maximum shock absorption

A-Flute is the original corrugated profile and still the best choice when products need gentle, protective “buffer zones.”

Best for:

- Glassware and ceramics

- Fresh fruits and vegetables

- Fragile, impact-sensitive goods

2.2 B-Flute: The Sturdy Workhorse

Height: 2.5–3.0 mm Flutes per meter: ~154 Primary strength: Crush resistance & stacking strength

B-Flute provides a flatter, denser structure that withstands compression and pressure. It’s ideal for shipping heavier items or boxes that will be stacked in warehouses.

Best for:

- Canned goods and hardware

- Books and media

- E-commerce shipping cartons

2.3 C-Flute: The Versatile All-Rounder

Height: 3.5–4.0 mm Flutes per meter: Mid-range Primary strength: Balanced cushioning + strength

C-Flute combines the cushioning capabilities of A-Flute with the stacking strength of B-Flute. It’s the most commonly used flute for standard shipping cartons.

Best for:

- General shipping needs

- Mixed-product fulfillment

- Most commercial packaging applications

2.4 E-Flute: The Printing Pro

Height: 1.1–2.0 mm Flutes per meter: ~295 Primary strength: High print quality + rigidity

E-Flute revolutionized packaging by making direct offset printing possible—eliminating the costly print-and-laminate step. Its smooth surface makes it ideal for retail packaging that needs to look premium on shelves.

Best for:

- Cosmetics and beauty products

- Small electronics

- Retail packaging & display boxes

- Inner dividers and compartments

2.5 F-Flute: The Ultra-Fine Luxury Flute

Height: 0.8 mm Flutes per meter: ~128 Primary strength: Exceptional printability & compactness

F-Flute is even finer than E-Flute, offering a remarkably smooth face ideal for luxury branding and small, intricate packaging.

Best for:

- High-end cosmetics

- Jewelry boxes

- Clamshell fast-food packaging

- Premium retail displays

3. Corrugated Board Types: How Many Layers Do You Need?

Flutes combine with linerboards to form different levels of board strength.

Single Face Board

- 1 liner + 1 flute

- Used for interior wrapping or padding

- Not suitable for standalone boxes

Single Wall Board (Most common)

- Liner + flute + liner

- Can be made with A, B, C, E, or F flute

- Used for most shipping boxes

Double Wall Board

- Two flutes + three linerboards (e.g., BC flute or BE flute)

- Provides higher stacking and crush resistance Great for: heavy items, industrial products, large shipments

Triple Wall Board

- Three flutes + four linerboards

- Strength comparable to wooden crates Used for: machinery, chemicals, and large export pallets

4. Flutes at a Glance: Quick Comparison Table

| Flute Type | Primary Strength | Best For | Analogy |

|---|---|---|---|

| A-Flute | Cushioning | Fragile goods | Shock absorber |

| B-Flute | Crush resistance | Heavy, stackable items | Load-bearing wall |

| C-Flute | Balanced strength | General shipping | Versatile framework |

| E-Flute | Print quality | Retail packaging | Sturdy foundation |

| F-Flute | Ultra-fine printing | Luxury goods | Precision finishing |

5. How to Choose the Right Flute: Practical Scenarios

Fragile glassware → Choose A-Flute

Maximum cushioning prevents breakage during transit.

Heavy books or canned goods → Choose B-Flute

Supports weight and resists deformation.

General e-commerce shipping → Choose C-Flute

A reliable, all-around performer.

Shelf-ready retail packaging → Choose E-Flute

Beautiful print surface + compact strength.

High-end cosmetics or jewelry → Choose F-Flute

Luxury look with excellent detail reproduction.

Industrial machinery → Choose Double or Triple Wall

Built for extreme loads and long-haul shipping.

6. Eco-Friendly Packaging: Recycling Corrugated Cardboard

Corrugated cardboard is one of the most recycled materials in global supply chains.

To recycle effectively:

- Remove all plastic and foam

- Flatten boxes to save space

- Cut out contaminated (greasy or wet) sections

- Leave labels and tape—they’re filtered out during pulping

Businesses: Consider balers or OCC recycling programs to minimize waste and reduce disposal costs.

Conclusion: Strong Packaging Starts with Smart Choices

A corrugated box isn’t “just a box”—it’s a precisely engineered structure designed to protect, support, and showcase your products. By understanding flute types (A, B, C, E, F) and board constructions, you can confidently select the right packaging for your needs, reduce damage risk, elevate branding, and optimize shipping costs.

When you choose the right flute, you choose the right armor for your product.

Frequently Asked Questions (FAQ)

For cushioning: A-Flute For stacking strength: B-Flute For balanced performance: C-Flute For print quality: E- or F-Flute

Corrugated has flutes for strength. Paperboard (like cereal boxes) is flat and suited only for lightweight items.

Not by default. However, coatings, wax treatments, or specialty liners can make it moisture-resistant.

Most e-commerce shippers rely on C-Flute or B-Flute for their balance of strength and cost.

Not necessarily. The “best” flute depends on:

– product fragility

– stacking needs

– branding requirements

– budget

– shipping distance