In today’s fast-paced retail environment, packaging must do more than just protect products—it must simplify logistics, accelerate shelf stocking, and visually engage consumers at the point of sale. Enter Shelf-Ready Packaging (SRP), also known as Retail-Ready Packaging (RRP)—a solution transforming how brands present themselves in stores.

From grocery aisles to warehouse clubs, SRP is becoming an essential tool for boosting operational efficiency and consumer appeal. But to unlock its full potential, businesses must understand its formats, benefits, and strategic applications.

What Is Shelf-Ready Packaging (SRP)?

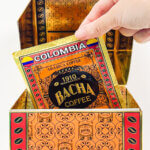

Shelf-Ready Packaging is a form of secondary packaging designed for seamless transition from transport to shelf display. It requires minimal handling, allowing retail staff to quickly place products on shelves while maintaining brand presentation.

Unlike traditional packaging, SRP emphasizes both functionality and visibility—helping reduce labor, improve product availability, and attract shoppers through organized, accessible displays.

Core Benefits of Shelf-Ready Packaging

Implementing SRP can deliver measurable improvements across the supply chain and in-store performance:

- Faster shelf stocking – Eliminates the need for unpacking and restocking individual items

- Improved brand visibility – Front-facing, well-organized displays draw customer attention

- Operational efficiency – Minimizes store labor, reduces training time for staff

- Eco-friendly materials – Often made from recyclable corrugated cardboard

- Increased impulse purchases – Eye-catching layouts drive spontaneous buying behavior

Types of Shelf-Ready Packaging: A Practical Comparison

Different SRP styles serve different retail goals. Here’s a breakdown of the most common types and when to use them:

| Type of SRP | Structure | Best For | Key Benefits | Common Retail Zones |

| Tray + Hood Packaging | Base tray with a removable top (hood) | Canned goods, bottles, toiletries | Protects in transit, quick to open, stable shelf display | Grocery, club stores |

| Wraparound Carton | Tight wrap enclosing grouped products | Bottles, jars, tubes | Compact, easy to open, space-efficient | Grocery aisles, convenience stores |

| Shelf Tray w/ Tear Panel | Low tray with perforated side or top | Cereals, snacks, frozen items | Quick access, clean design, improved visibility | Refrigerated units, mid-shelf |

| PDQ Display Unit | Preloaded mini displays with graphics | Impulse buys, cosmetics, trial packs | Plug-and-play setup, high visual appeal | End caps, checkouts, promos |

| Stackable Tray Units | Modular, interlocking trays | Bulk or high-volume items | Space-saving, efficient stocking | Warehouse clubs, wholesale stores |

| Divider Box Display | Tray with integrated dividers | Fragile or luxury goods | Prevents product shifting, premium look | Boutique shelves, specialty retail |

You May Also Want to Know…

Designing Effective Shelf-Ready Packaging

To design impactful and compliant SRP, keep these factors in mind:

✅ Retailer Requirements

Major retailers have strict SRP guidelines. For instance, Walmart requires packaging to be strong yet easy to open, while Costco prefers modular stackable units. Always tailor your SRP design to the specific store’s standards.

✅ Product Dimensions & Weight

Heavier items may need reinforced packaging. For lighter or irregularly shaped items, divider inserts or snug trays prevent damage and disorganization.

✅ Branding & Visual Impact

Treat SRP like an extension of your brand. Incorporate bold colors, logos, and callouts to stand out, even in a crowded aisle.

✅ Sustainability Goals

Consumers and retailers alike are demanding eco-conscious solutions. Use recyclable materials and avoid plastic coatings or unnecessary packaging layers.

When Should You Use Shelf-Ready Packaging?

Shelf-ready solutions are ideal for:

- Fast-moving consumer goods (FMCGs) such as snacks, beverages, and personal care items

- Seasonal launches or limited-time promotions

- Multipacks and bundle offers

- High-turnover retail spaces including grocery chains, pharmacies, and big-box stores

If your product needs high visibility, rapid restocking, or sustainable packaging, SRP is worth the investment.

Frequently Asked Questions (FAQ)

Q1: Is Shelf-Ready Packaging more expensive than traditional packaging?

A: Initially, SRP can cost slightly more in design and production. However, the savings from faster stocking, reduced labor, and better shelf presence typically offset the investment.

Q2: Can SRP be used in e-commerce or D2C channels?

A: While SRP is designed for physical retail, some formats can be adapted for unboxing experiences or subscription kits that enhance brand interaction in direct-to-consumer sales.

Q3: How do I know which SRP format is right for my product?

A: Consider your product size, weight, retail channel, and how often it needs restocking. Consulting with a packaging engineer or supplier can also help tailor a solution.

Q4: What’s the environmental impact of SRP?

A: Many SRP designs use corrugated cardboard, which is both recyclable and biodegradable. Plus, reduced handling and fewer damaged goods mean less overall waste.

Q5: Are there industry standards for Shelf-Ready Packaging?

A: Retailers like Tesco and Walmart have published SRP guidelines. Packaging providers also follow standards from groups like the Consumer Goods Forum and ISTA for durability and sustainability.

Conclusion: Packaging That Performs Beyond the Box

Shelf-Ready Packaging is more than a shipping solution—it’s a strategic retail asset. By aligning your SRP design with retailer needs, consumer behavior, and sustainability goals, you’ll streamline logistics while elevating your brand on the shelf.

Looking to make your packaging work smarter? Consider partnering with packaging experts to explore custom SRP options tailored to your products and retail strategy.